For interior floors, dense natural stone such as granite and marble are generally crystallized or polished to give them all their splendor.

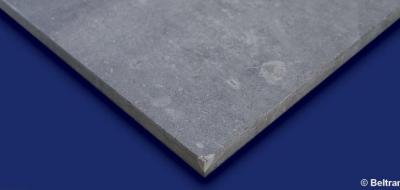

However it is also possible to realize sanded, honed (matte), satin finishes according to the desires of the customer and the type of stone. Blue stone for example is often honed given its low resistance to wear.

Depending on the type of finish, it will be important to protect your floor appropriately. More info

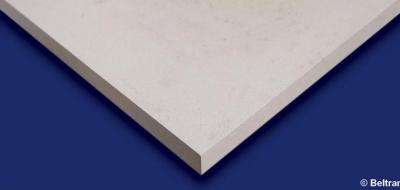

The sanded finish is a classic finish for hard outdoor stone. To obtain this finish, the floor is roughly sanded in order to remove the traces of the tile saw. However, the traces of diamond (or any other abrasive used during grinding) remain visible.

The advantages of this finish are the low cost and the anti-slip properties of the floor.

The honed finish is a matte or slightly satin finish and the traces of grinding are no longer visible. It is therefore situated between the sanded (visible traces) finish and the satin finish (visible gloss).

This finish is obtained by grinding and diamond polishing or with conventional abrasives.

The honed finish can be combined with a color enhancer and/or a water and oil repellent depending on the desired color and protection of the floor.

The smaller the grain, the more gloss is obtained. Depending on the number of steps realized, the desired gloss obtained will be a satin or polished.

Polishing of the stone will enhance its natural color but the different treatments can still be applied. Grinding opens the stone and reveals the structure.

We often speak about crystallization of polished stone. This term (very large and often overused) basically covers additional treatments to polish stones to obtain a high gloss mirror effect. More info…

The high gloss finish (mirror or water finish) is considered a finish obtained by the method of crystallization or similar methods.

This finish is obtained by means of a physical-chemical treatment of the stone through crystallization with powder, a traditional technique or mixed technique depending on the type of stone or its nature.

Besides the aesthetic aspect, the gloss finish closes the pores of the stone to extend the lifetime of the floor and its overall resistance. This is the most common finish for indoor floors in marble or granite.

The Lupoclean finish (also a treatment) is applied to a finished floor (most often a honed finish) and allows to increase resistance to wear, chemical resistance, resistance to stains and to enhance the colors of the floor and most importantly makes the floor maintenance friendly.

Finishing with Lupoclean gives the floor a satin and no-slip surface (R9) finish, the hardness is increased ( 1 to 2 points on the Mohs scale compared to the original hardness of the stone). A higher anti-slip finish is also possible (R10 or R11).

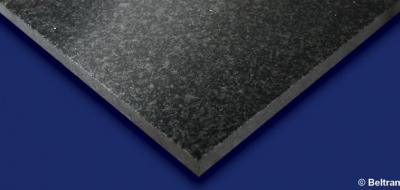

In addition to a sanded and honed finish it is possible to opt for a bush-hammered or flamed finish for no-slip surface qualities.

During bush-hammering, the floor is processed with carbide wheels. These wheels serve as small hammers in order to give the floor texture and to remove all previous treatments. The aspect of a bush-hammered floor will vary depending on the type of stone and the type of wheels used. However, it is almost impossible to obtain the original appearance. This technique can also be used for concrete.

Flamed natural stone has a no-slip surface and aesthetically attractive finish. This operation is realized by heating the floor surface with a burner and afterwards cooling it down with buckets of water. The thermal shock creates small fracture lines along the grains on the surface.

This finish can only be applied on large surfaces and hard stone. The edges however (visible or invisible) cannot be flamed.